About ecoRevo

ecoRevo® is an earth-friendly revolution aimed at a sound material-cycle society with recycled tiles.

ecoRevo's opportunity

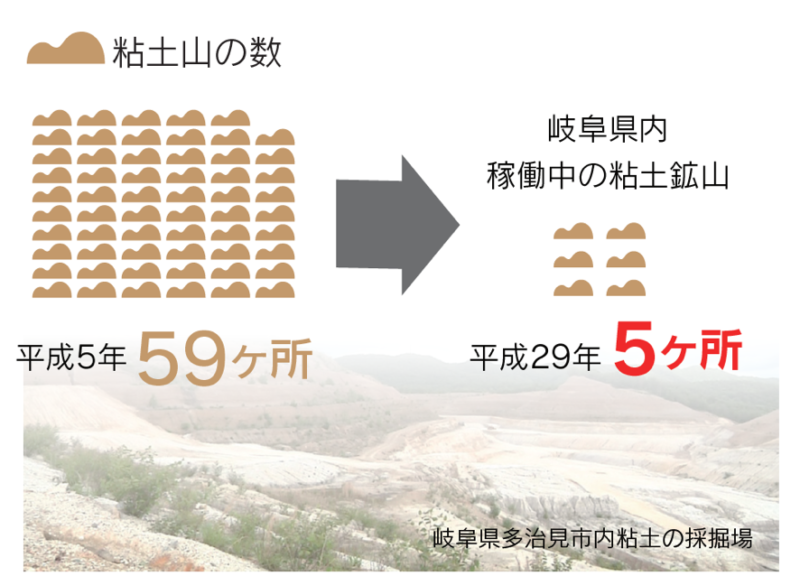

The issue with tile resource depletion

Tajimi City, a place that has been famous since ancient times for producing ceramics such as Mino pottery, has long boasted about being one of the leading producers of tile inside Japan. As a result of a sluggish economy and the closure of mines due to clay depletion, the development of alternative raw materials that do not depend on natural materials has become an urgent matter.

Japan's disposal situation

As of March 2018, there are 1103 waste disposal facilities and 1651 final disposal sites in Japan; furthermore, the country has the most disposal facilities and final disposal sites in the world. It is said that up to 70% of the world’s incineration sites are in Japan. Due to Japan having such a small land area, “disposal of garbage = burning” has become the mainstream.

At the same time, it is also said that because the country discharges a large amount of trash, Japan also has some of the world’s best technology to help reduce the amount of garbage. The foremost leading technology is the melting furnace.

SDGs and growing environmental awareness

In September 2015, all United Nations member countries (193 countries) decided to protect our planet by eliminating extreme poverty, inequality and injustice over the next 15 years in order to realize a better future; this plan, which was adopted by the United Nations, was named “Agenda 2030”. This plan is part of the “Sustainable Development Goals”, which is often referred to as SDGs. In addition to challenges that were not fully addressed within the Millennium Development Goals, and by addressing 17 goals and 169 targets, such as the serious environmental issues discussed at Rio + 20, SDGs are an epic challenge to realize a world where “no one is left behind”.

SDGsは、ミレニアム開発目標で十分に手を打てなかった課題に加え、Rio+20で議論された深刻化する環境課題など、17の目標と169のターゲットに全世界が取り組むことによって『誰も取り残されない』世界を実現しようという、壮大なチャレンジです。

Recycled Tile

日本のタイル産業の今後に関わる課題、そして世界が直面するゴミ問題を解決するための方法として、弊社が辿り着いたひとつの答えが「リサイクルタイル」です。

弊社は、タイルメーカーが集結する、国内有数のタイル産地・多治見市で「企画開発型タイル商社」として、長年タイルに関わってきました。地元のタイルメーカーとの豊富なネットワークを活かしたオーダーメイドタイルの製作を得意とし、国内外の有名物件への納品実績も多数あります。また、社内にタイルの生産設備を揃えており、新製品の研究・開発にも力を入れてきました。

弊社のリサイクルタイルの歴史は、弊社代表・笠井政志の父親の代にまで遡り、25年にわたる基礎研究を経て培われた技術です。2019年には、社内のエコロジー事業を本格化させるために「エコレボ事業部」を発足。研究開発の新拠点として「エクシィズ・ラボ」も新設し、リサイクルタイルの開発体制を強化しました。

-

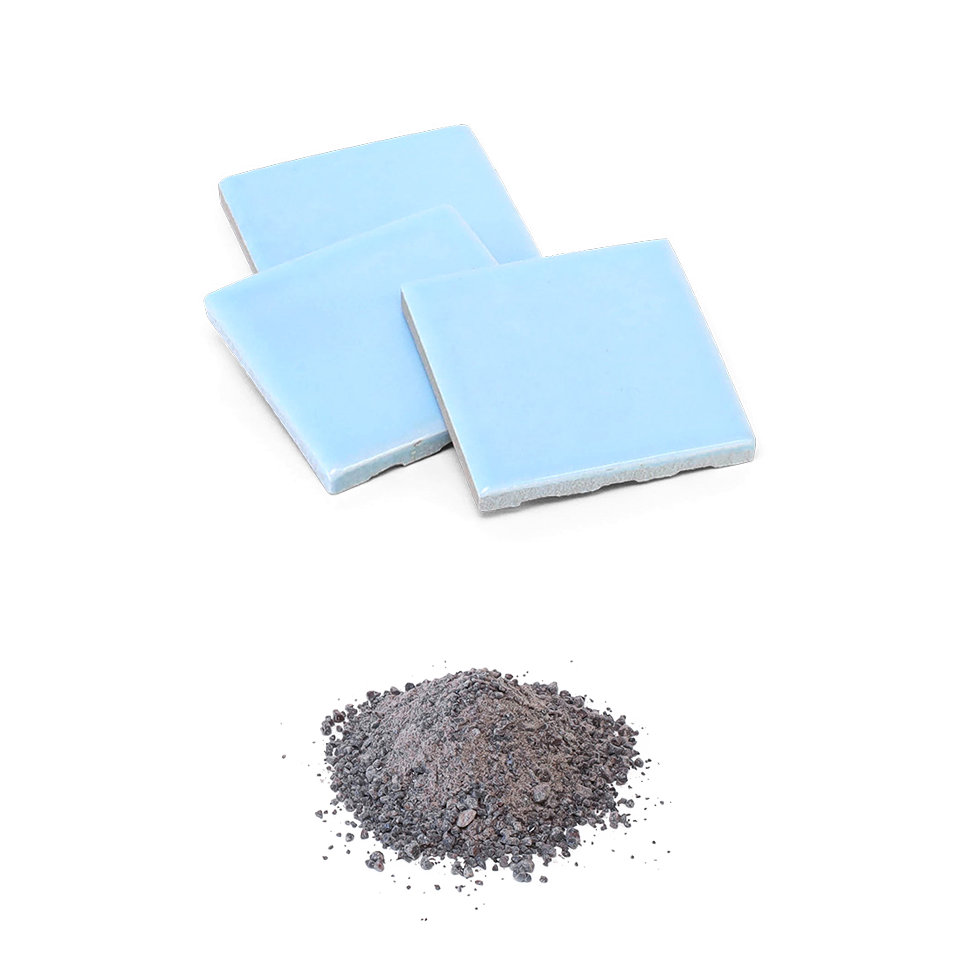

溶融スラグ

-

溶融スラグ

-

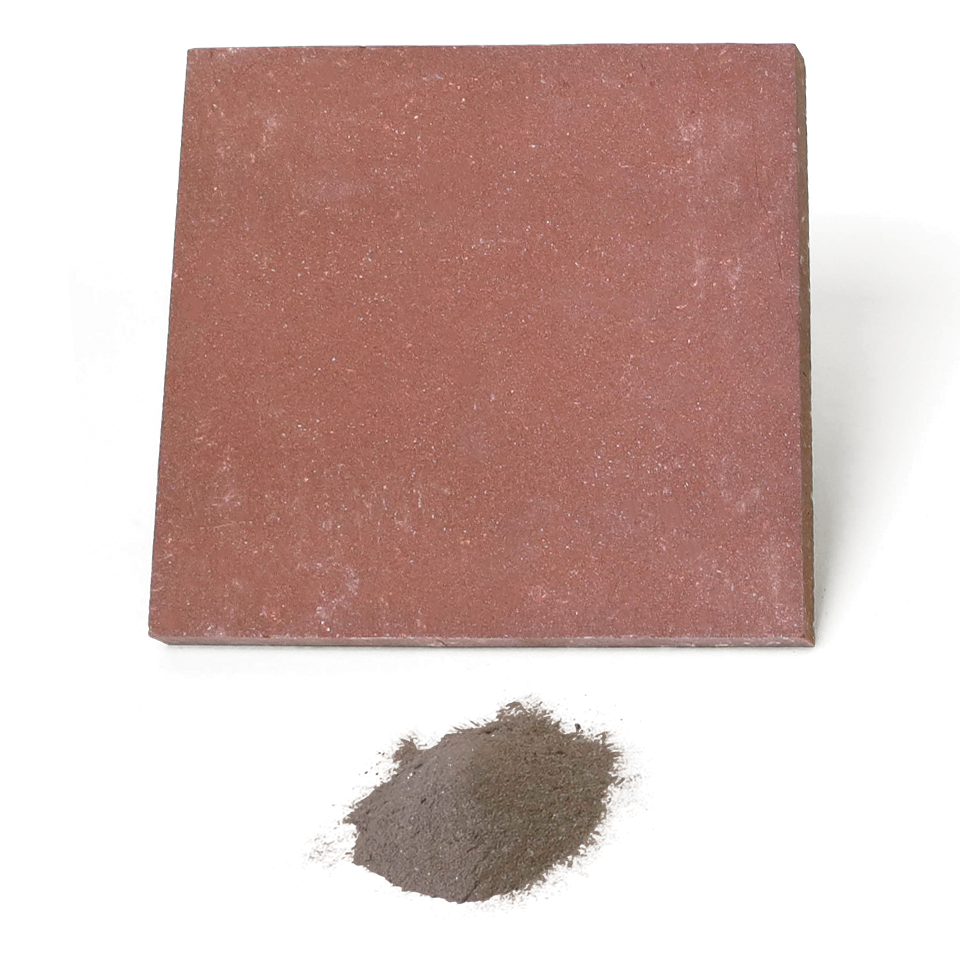

バイオマス発電 煤塵

-

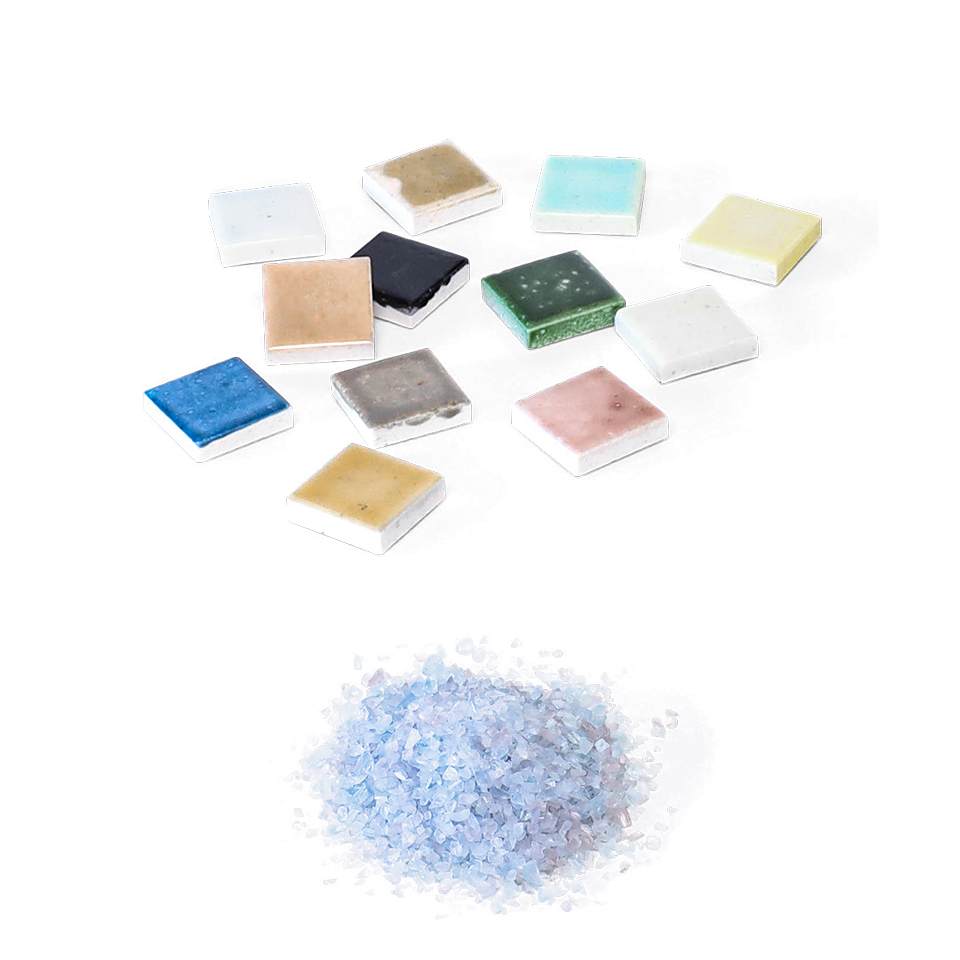

廃ガラス

ecoRevo®のリサイクルタイルは、リサイクル率95%以上を実現! これはグリーン購入法適合タイルの条件(リサイクル率20%以上)を遥かに超える数値です。また、低温かつ短時間での焼成が可能で、製造時のCO2排出量を17~33%削減。エネルギー効率の良い「省エネタイル」でもあります。

溶融スラグ以外にも、廃ガラスやセラミック廃材、バイオマス発電所から排出される煤塵(ばいじん)などのリサイクル原料化にも成功し、応用の可能性はさらに広がっています。

溶融炉と溶融スラグ

溶融炉は、ゴミを安全・コンパクトに処理できる注目の技術です。ゴミを1300~1700℃の高温で溶かすことで減容化・無害化し、医療系廃棄物やダイオキシン、アスベストなども安全に処理できるため、日本全国で導入が進んでいます。

この溶融炉から排出された黒いガラス状の「溶融スラグ」は、リサイクルが可能で、現在、道路の路盤材やコンクリートの原料として活用されています。弊社は、この溶融スラグをタイル原料に活用する技術を、長年研究してきました。

溶融スラグ

リサイクルタイルを購入したい

ecoRevo® がレギュラー製品として販売しているリサイクルタイルをご購入いただけます。製品ラインナップは順次追加予定。既製品をもとに、お好みの色やサイズなどを指定する「特注オーダータイル」をご依頼いただくことも可能です。

SDGsが注目される昨今、サステナブル建材は、公共事業や商業施設等のプレゼンの際にも大きなアピールポイントとなり、採用の決め手にもなり得ます。

まずはサンプルのご請求から、お気軽にご相談ください。

循環型社会(循環型経済 / サーキュラーエコノミー)という言葉をご存じでしょうか? 資源をできるだけ長く循環させながら再利用することで、廃棄物などの無駄を富に変える、地球環境に優しい社会モデルのことです。

ecoRevo®が目指すのは、まさにこの「循環型社会」です。タイルを通じて、長年世界の建築物件に関わってきた弊社が、これからの社会のためにできることは、高品質なリサイクル技術を確立し、タイル製造の新たな経済モデルを生み出すことだと考えています。

現在、私たちの理念に共感いただいた自治体や企業の方たちとタッグを組み、循環型社会の実現に向けて、リサイクルタイルの研究・開発を推し進めています。

エコレボが目指す、地球にやさしい経済サイクル

-

リサイクルタイルの試作品の数々

-

リサイクルタイルの採用事例(多治見市)

-

リサイクルタイルの採用事例(豊田市)

-

SDGs関連のイベントに参加

-

ぎふ地域ベンチャー支援ネットワーク「NOBUNAGA21」にて、最優秀賞(2019年度)を受賞。

-

研究・開発のようす